Posts Tagged ‘Community College System of New Hampshire’

Thursday, June 7th, 2018

1: The state of New Hampshire’s booth at the BIO International this week in Boston. 2: Shawn Cain, right, COO of LSNE Contract Manufacturing and BEA Commissioner Taylor Caswell. 3: Caswell and President/CEO Thomas Taylor, right, of Foxx Life Sciences. 4: Caswell and David Alward, right, Canada’s Consul General to New England. 5: The NH pavilion team: Business and Economic Affairs; the University of New Hampshire; the Advanced Regenerative Manufacturing Institute; the Community College System of New Hampshire; Dartmouth College and the New Hampshire High Tech Council. New Hampshire showcased its fast-growing biotech/medtech industry, its academic partners, and its quality of life at the annual BIO International Convention in Boston, Mass. this week. Now in its 25th year, the event draws over 17,000 people and 1,800 exhibitors from all over the world.

The Department of Business and Economic Affairs partnered with the University of New Hampshire; the Advanced Regenerative Manufacturing Institute; the Community College System of New Hampshire; Dartmouth College and the New Hampshire High Technology Council to present a collaborative and interactive experience for biotech companies, biotech talent, executives, startups, and other stakeholders for the three-day conference.

“This is a prestigious and respected trade show that’s been around for 25 years and it was time that New Hampshire got in front of an international audience to talk about what we have going on here,” said Taylor Caswell, commissioner of the Department of Business and Economic Affairs. “We have trailblazing companies that are changing healthcare around the world.”

Caswell visited with several New Hampshire companies taking part in the show, including Foxx Life Sciences of Salem, Lonza Biologics of Portsmouth, and LSNE Contract Manufacturing of Bedford.

“Each of these companies has a major footprint in New Hampshire and they are continuing to grow,” he said. “They are finding the talent they need here and a business climate conducive to growth, but we want to do everything we can to continue to support their goals and provide quality jobs for New Hampshire.”

Caswell also met with David Alward, Canada’s Consul General to New England for a wide ranging discussion about life sciences, trade and tariffs.

“We share a $5 billion border with Canada,” Caswell said, “and for many of our businesses, small or large, the relationship with Canada is critical. We need to do what we can to protect that.”

Throughout the three-day conference, New Hampshire’s team promoted the state’s exceptional business climate and lifestyle assets; from education pathways and life science startups to how to match up its outstanding academic institutions, their research, and their graduating workforces with companies across the state.

“New Hampshire is poised to be at the forefront of innovation and healthcare and the leaders of pharma and biotech from around the world got to see that the BIO International Convention,” Caswell said.

Tags: Advanced Regenerative Manufacturing Institute, BIO International Convention, Community College System of New Hampshire, Dartmouth College, Foxx Life Sciences, LSNE Contract Manufacturing, NH High Technology Council, University of New Hampshire

Posted in NH Business Matters | Comments Off on NH Recruits for High-Growth Biotech Talent at International Conference

Tuesday, March 11th, 2014

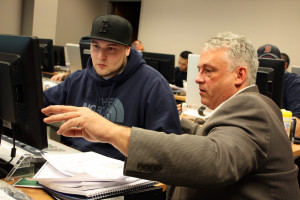

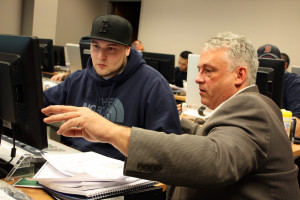

Great Bay Community College’s CNC training program is collaboration with SIG Sauer and our friends at AMPed NH explain its great value to students and employers. Ed.

Innovative boot-camp-style training programs offered by New Hampshire’s Advanced Manufacturing Partnerships in Education are benefiting not only scores of community college students, but also employers statewide.

Programs like Great Bay Community College’s CNC Production boot camp can save precision manufacturers money and time. Programs like Great Bay Community College’s CNC Production boot camp can save precision manufacturers money and time by teaching the exact hard and soft skills they require, using the same equipment they use. Learning takes place away from production floors, allowing staff to focus on meeting product deadlines and exceeding standards. At the same time, boot camps can turn over new qualified candidates in a matter of weeks, building a healthy pipeline of qualified career prospects.

Offered in an accelerated eight-week format, the CNC Production boot camp is instructed by field experts and offered on-site at AMPed NH industry partner SIG Sauer’s state-of-the-art firearms manufacturing facility on Pease International Tradeport.

Collaboration starts at the very beginning. Community colleges work in concert with industry partners to develop and deliver specifically targeted training programs such as the CNC (computer numerically controlled) boot camp, which readies students for high-demand, well-paying CNC machining careers.

But job seekers aren’t the only ones clambering to sign up. Current SIG Sauer employees, with support from their company, are also receiving training in preparation for advancement.

Freedom Chandavong, 23, of Newmarket, a two-year employee at SIG, started in packaging and shipping and is already advancing within the company. He’s in the boot camp to prepare for a career in composite component production. SIG Sauer supports his ambitions by providing tuition reimbursement and time to train.

Just two days into boot camp, Chandavong said, the depth of topics covered was impressive.

“We were already getting into hands-on simulation training,” Chandavong said. Simulators allow students to identify and correct design and production problems in a safe, supportive learning environment before moving on to actual production equipment.

“In today’s precision manufacturing, ‘good enough’ doesn’t count,” said Chandavong, and boot camp has bolstered his confidence and determination. “SIG has made a commitment to me, and I’m going to return that commitment. I’m not going to fail them. For me, this is not a job; this is a career – and with the composites industry growing, there’s a future here.”

The commitment is not unusual, as exhibited by the students who routinely hang back in the lab, celebrating new breakthroughs even as break times begin.

“The application process does a good job to identify those with passion,” said boot camp program developer Sean Hoeing.

Innovative boot-camp-style training programs benefit students and employers. The thought was echoed by instructor Jeff Bean, an inventor and engineer whose own products are sold nationally and used in the teaching lab.

“It’s impressive,” Bean said. “They come in at different levels. They tend to be hands-on learners, and that’s what we want. That, combined with patience and attention to detail.

“We get to see them at the beginning of their training and then as they progress,” Bean said. “There are so many career paths they can choose.”

Indeed, the boot camp model has been a successful workforce solution for AMPed NH industry partners all over the state, who in years past have reported concerns that the pool of these high-tech employees was drying up.

Many students from AMPed NH’s myriad industry-approved advanced manufacturing certificate and degree programs, have already been hired by partners like SIG Sauer, who view the programs as reliable recruiting grounds for their growing operations.

The boot camp’s location itself speaks to that growth, as well as the demand for a more robust STEM (science, technology, engineering and math) workforce; SIG Sauer expanded to the site after outgrowing operations in Exeter. In addition to its Exeter and Pease sites, the company operates a training center in Epping and is opening another facility in Dover, as well as sites outside America. Combined, dozens of new hires are anticipated in the coming months locally.

Computer-numerical controlled machines are widely used where very precise manufacturing is required. Unlike manually operated equipment of the past, CNC machines shape components automatically by reading computer design code. They are faster and more versatile than ever before.

Under AMPed NH, funded by a $20 million federal TAACCCT grant from DOL’s Employment and Training Administration, NH’s seven community colleges offer dozens of programs in disciplines including robotics & automation; electronics and electromechanics; advanced machine tool, composites and welding technologies; and engineering & programming.

To learn about upcoming CNC Production boot camps, contact Sean Hoeing at shoeing@ccsnh.edu. To learn about all advanced manufacturing programs offered by AMPed NH, visit www.ampednh.com.

Desiree Crossley

Marketing Coordinator

Advanced Manufacturing Partnerships in Education

Community College System of NH

Tags: advanced manufacturing in New Hampshire, AMPedNH, Community College System of New Hampshire, Great Bay Community College, New Hampshire Department of Resources & Economic Development, New Hampshire Division of Economic Development, Sig Sauer

Posted in NH Business Matters | Comments Off on Boot Camp-style Training Gets Advanced Manufacturing in Shape for the Future

Thursday, December 15th, 2011

CONCORD – Gov. John Lynch and the Executive Council on Wednesday approved a $4 million Business Finance Authority loan to complete a major economic development agreement between the State, Safran USA, and the City of Rochester. CONCORD – Gov. John Lynch and the Executive Council on Wednesday approved a $4 million Business Finance Authority loan to complete a major economic development agreement between the State, Safran USA, and the City of Rochester.

The agreement will enable the construction of a previously announced 275,000 square-foot facility, in which Safran USA and Albany Engineered Composites (AEC) will be co-located. The facility will employ approximately 400 workers. The State, through the Department of Resources and Economic Development, worked with Albany, Safran USA and the City of Rochester to ensure an agreement could be reached.

“We have been working closely with Safran USA and Albany to see the project through to completion. Today’s news is a major economic development win for Rochester and the entire state of New Hampshire, and will result in the creation of hundreds of jobs,” Gov. Lynch said.

As part of the effort to recruit the new facility, the state has also partnered with Great Bay Community College to create a new composite manufacturing curriculum to train workers to fill the new jobs.

“Safran USA and Albany could have located their new facilities anywhere in the country, but they chose New Hampshire because they recognize that we have a strong workforce and a winning economic strategy. We worked intensely with the companies over the past several years to make the construction of this new plant, and the hundreds of jobs that come with it, a reality,” Gov. Lynch said.

“I want to thank (DRED) Commissioner George Bald and his staff, particularly state business recruiter Cindy Harrington, as well as New Hampshire’s Business Finance Authority, under the leadership for Jack Donovan, for getting us to where we are today. I also want to thank Mayor T.J. Jean and Rochester city officials for their work and commitment to this project,” Gov. Lynch said.

“Finally, I want to thank Albany International’s President and CEO Joseph Morone and Safran USA leadership for their commitment to New Hampshire and for working cooperatively to move this critical project forward.”

“This agreement, and the manufacturing plant and new jobs that will result from it, is a reflection of not only the strength of the relationship between the State of New Hampshire, the City of Rochester, Albany International and Safran USA, but also of how tightly our futures are connected. The efforts of Governor John Lynch and his team in this process cannot be overstated, and the new plant and new jobs that will be created are the direct result of his efforts on behalf of State of New Hampshire,” said Albany President and CEO Joseph Morone.

The new facility will manufacture composite engine components.

“We are very pleased to launch the construction of a manufacturing plant in Rochester, where the Safran group and AEC will combine their resources in order to produce advanced composite parts for the LEAP aircraft engines developed by CFM International, a 50/50 joint company between Safran and GE,” said Peter Lengyel, President and CEO of Safran USA, Washington D.C. Operations.

Albany Engineered Composites is a subsidiary of Albany International, Corp., which employs about 225 workers at its existing Rochester facility. Last year, the company relocated its corporate headquarters from New York to Rochester.

“The City of Rochester is honored to be selected by Safran USA and Albany Engineered Composites to host their new world-class advanced manufacturing facility. This investment demonstrates Rochester’s commitment to attracting and securing sustainable industrial development and providing valuable jobs to our local economy,” said Rochester Mayor T.J. Jean. “Today’s announcement is a milestone for Rochester as we emerge from these difficult economic times.”

“This is a great day for Rochester and for the state of New Hampshire as a whole,” said Commissioner George Bald. “We thank Safran USA for making the decision to locate their facility in New Hampshire and commend the City of Rochester for its hard work in bringing in a quality company that will create new jobs and add to the economic vitality of our state.”

Construction of the new plant, near the existing Albany facility, will begin in the spring of 2012.

Tags: Albany Engineered Composites, Albany International, Business Finance Authority, CFM International, Cindy Harrington, City of Rochester, Community College System of New Hampshire, Corp., Granite State Business Park, Great Bay Community College, Jack Donovan, Joseph Morone, Karen Pollard, LEAP Aircraft Engines, New Hampshire, nh, NH Department of Resources and Economic Development, Peter Lengyel, Rochester Economic Development Corporation, Rochester Housing Authority, Safran Group, Safran USA, T.J. Jean

Posted in NH Business Matters | Comments Off on 400 New Advanced Manufacturing Jobs to Be Created in Rochester, NH

Tuesday, September 27th, 2011

The Community College System of New Hampshire (CCSNH) has been awarded $19.9 million, the largest grant in the System’s history, to develop training programs that will support NH’s advanced manufacturing industry.

The funds will enable the state’s seven community colleges, located in every region of New Hampshire, to develop programs that prepare individuals for skilled employment to meet current and emerging workforce needs in advanced manufacturing in New Hampshire. The programs will focus on displaced workers and other job-seekers by providing training opportunities at multiple professional levels in skills linked to regional employment. The funds will enable the state’s seven community colleges, located in every region of New Hampshire, to develop programs that prepare individuals for skilled employment to meet current and emerging workforce needs in advanced manufacturing in New Hampshire. The programs will focus on displaced workers and other job-seekers by providing training opportunities at multiple professional levels in skills linked to regional employment.

The CCSNH grant proposal was titled the Regional Advanced Manufacturing Partnership: Elevating NH’s Workforce to Meet the High-Tech Skill Demands Of NH’s Rapidly Advancing Manufacturing Sector, or “Ramp-Up.” “This program is all about bringing high-quality jobs to New Hampshire, ensuring that we have the workforce to fill those jobs, enable business located here to grow, attract new companies, and increase economic activity,” said J. Bonnie Newman, Chancellor of the Community College System.

“Manufacturing is a critical driver of economic growth and employment in our state,” said U.S. Senator Jeanne Shaheen. “However, as businesses replace traditional manufacturing methods with advanced technology, many job-seekers have been unable to keep up because they lack the specialized skills required. By arming workers with the tools needed to excel in advanced manufacturing, this award will help New Hampshire workers secure high-paying jobs and help New Hampshire companies hire high-quality employees.”

“With manufacturing as such an important part of New Hampshire’s economy, a key part of our successful economic strategy has been training our workers in advanced skills so they can keep up with changing technology, and our businesses can continue to compete globally. This grant is exciting news for our state, our workers and our businesses. This is a tremendous amount of funding that will allow us to expand our worker training efforts, which will help more companies grow and compete,” Gov. Lynch said. “This is great news for New Hampshire’s economy.”

CCSNH’s efforts will target advanced manufacturing sub-sectors inculding automation and robotics, precision manufacturing, advanced machine tool technology, mechatronics, advanced materials technologies and composites, precision welding, automation and process control, and energy systems for precision manufacturing.

“This funding comes at a very important time, since students and the college population in New Hampshire have been disadvantaged by state budget cuts and decreased access to education and training opportunities,” said Newman. “While this grant will not replace state funds that were cut, it will make possible focused efforts in partnership with NH businesses to create educational and career ladders for advanced manufacturing jobs, a key industry here in New Hampshire and in the nation.”

“New Hampshire’s community colleges are uniquely situated to provide these opportunities and work in partnership with employers,” Newman said. “We have campuses in every region of the state. NH companies already look to the community colleges to train a local workforce in high-need skills like health care and technology. The community colleges are adept at providing access to students of all ages, backgrounds, and aspirations, and we have already developed strong partnerships that enable students to continue their education to the baccalaureate level and beyond.”

The CCSNH proposal was developed in close collaboration with over a dozen NH manufacturing companies from across the state. The industry partners provided data on current and future workforce needs, skills gaps of the current workforce and job applicant pool, industry trends, and specific equipment and types of training key to their ability to thrive and compete globally. Other partners in the application included the Business and Industry Association of New Hampshire, the NH High Tech Council, the Advanced Manufacturing Education Advisory Council, the NH Department of Resources and Economic Development, the NH Department of Labor, NH Employment Security, and the NH Department of Education.

Jim Roche, president of the Business and Industry Association of NH, said, “If we expect to retain and grow companies in New Hampshire’s leading economic sector – advanced manufacturing – we need to ensure alignment between training provided through our educational institutions and the needs of manufacturers and high technology employers. This grant represents a great opportunity to further that goal.”

George Bald, Commissioner of the NH Department of Resources and Economic Development, said, “This grant will have a tremendous impact on the NH workforce, on the quality of jobs that come to the state, and on the strength of the manufacturing industry in New Hampshire. The close collaboration between the community colleges and our NH employers to identify skill areas and training needs reflects the excellent working relationship that exists in New Hampshire to strengthen our workforce.”

CCSNH applied for the grant through the U.S. Department of Labor’s Trade Adjustment Act-Community College Career and Training Grant program.

Tags: Advanced Manufacturing Education Advisory Council, Business & Industry Association of New Hampshire, CCSNH, Community College System of New Hampshire, J. Bonnie Newman, Jeanne Shaheen, Jim Roche, New Hampshire Department of Education, New Hampshire Department of Resources & Economic Development, New Hampshire High Tech Council, NH Department of Labor, NH Employment Security, U.S. Department of Labor

Posted in NH Business Matters | Comments Off on Manufacturing Industry in NH to Get $19.9 Million Shot-in-the-Arm

Thursday, April 1st, 2010

Network New Hampshire Now (NNHN), a collaboration of public and private partners from across the state, submitted a $66 million proposal to the National Telecommunications & Information Administration’s Broadband Technology Opportunities Program (NTIA BTOP) to fund critically needed broadband expansion in New Hampshire. The proposal, submitted on behalf of NNHN by the University of New Hampshire March 26, calls for building a middle-mile fiber optic network that will connect homes, businesses and community organizations to help advance economic development, education, health care and public safety across the state. NTIA will decide by late summer whether to accept the proposal.

“The middle-mile fiber network is seen as a major opportunity for economic development. In particular, the network designed for New Hampshire has openness as its core purpose – it will enable affordable choices for all providers to reach areas of the state that have been difficult to service,” said George Bald, commissioner of the state Department of Resources & Economic Development (DRED), one of the collaborating partners involved in the grant application. “The Network New Hampshire Now proposal puts the state on par with international fiber optic broadband capacity and capability.” “The middle-mile fiber network is seen as a major opportunity for economic development. In particular, the network designed for New Hampshire has openness as its core purpose – it will enable affordable choices for all providers to reach areas of the state that have been difficult to service,” said George Bald, commissioner of the state Department of Resources & Economic Development (DRED), one of the collaborating partners involved in the grant application. “The Network New Hampshire Now proposal puts the state on par with international fiber optic broadband capacity and capability.”

The NNHN project will expand broadband in all 10 counties in New Hampshire in three ways. First, existing middle-mile fiber from the Seacoast, across to the southwest, up to the northwest, on to the North Country, and through the Lakes Region will be expanded and new fiber will be put in place. Second, an innovative model called FastRoads will be implemented to provide fiber optic connectivity in communities, starting with Rindge, in the southwest near the Massachusetts border and Enfield in western New Hampshire. Finally, the project includes the construction of a middle-mile microwave network for public safety, public television and mobile broadband communications on mountaintops across New Hampshire.

In addition to UNH and DRED, NNHN partners include the Community Development Finance Authority, all University System of New Hampshire institutions, the Community College System of New Hampshire, the Keene Municipal Broadband Committee, Southwest Regional Planning Commission, North Country Investment Corporation, town managers in Hanover and Keene, state legislators, and telecommunications vendors.

“UNH is proud to submit this proposal on behalf of the citizens of New Hampshire,” said Joanna Young, chief information officer at UNH. “A key strength of this proposal is the public and private partnership it represents, as well as its scope and reach.”

The NNHN initiative is endorsed and supported by numerous entities that understand its potential to expand broadband in the state and provide high speed access to areas where such access will have an instant impact on economic development efforts. Numerous letters of support have been received from hospitals, libraries, business associations, state legislators, and university presidents.

“The growth engine of education, health services, and economic development requires this technology to help New Hampshire be competitive today and in the future,” said Scott Valcourt, the principal investigator at UNH for the grant proposal. “With NTIA funding, the dream of an open access, high speed broadband network will be realized.”

Tags: Community College System of New Hampshire, Community Development Finance Authority, Joanna Young, Keene Municipal Broadband Committee, National Telecommunications & Information Administration, Network New Hampshire Now, New Hampshire Department of Resources & Economic Development, North Country Investment Corporation, Scott Valcourt, Southwest Regional Planning Commission, University of New Hampshire

Posted in NH Business Matters | Comments Off on Statewide Collaborative Seeks Broadband Expansion

Wednesday, September 16th, 2009

Plans for high speed linkages that connect Northern New Hampshire to Manchester and extend into additional networks in Northern New England received a major boost when the National Science Foundation (NSF) announced a $1.2 million grant to support building this fiber path. The funds will create new linkages among higher education institutions in New Hampshire, including the University of New Hampshire, Plymouth State University and Dartmouth College to help support collaborative research and education initiatives regionally, nationally, and internationally.

Funds are being awarded through the NSF’s EPSCoR (Experimental Program to Stimulate Competitive Research) Office’s Research Infrastructure Improvement Program Track-2 grant (RII Track-2). The University of New Hampshire, which hosts the New Hampshire EPSCoR Office, is the grant recipient. The University System of New Hampshire operates the current network that serves its four institutions and provides Internet and connectivity services to the Community College System of New Hampshire, and several K-12 schools, libraries, public service centers, and public health and safety organizations across the state. These funds will, in part, help advance larger efforts to develop a regional optical network that will have significantly greater bandwidth speed and help address current and future bandwidth demands. Funds are being awarded through the NSF’s EPSCoR (Experimental Program to Stimulate Competitive Research) Office’s Research Infrastructure Improvement Program Track-2 grant (RII Track-2). The University of New Hampshire, which hosts the New Hampshire EPSCoR Office, is the grant recipient. The University System of New Hampshire operates the current network that serves its four institutions and provides Internet and connectivity services to the Community College System of New Hampshire, and several K-12 schools, libraries, public service centers, and public health and safety organizations across the state. These funds will, in part, help advance larger efforts to develop a regional optical network that will have significantly greater bandwidth speed and help address current and future bandwidth demands.

“This research and corresponding network development will thrust New Hampshire and the northeast region into the international research stage with the ability to collaborate with cyber-enabled tools and resources in ways that have not yet been possible,” said Scott Valcourt, UNH director of project management and consulting services for information technology and the New Hampshire principal investigator. “That research will have other economic development and quality of life benefits for New Hampshire citizens.”

The grant is a result of collaborative work by multiple NSF EPSCoR states that helped form the Northeast Cyberinfrastructure Consortium (NECC) in 2006. Officials in Maine, New Hampshire, Rhode Island, Vermont, and Delaware initiated two related efforts to identify and promote the shared use of research facilities across the region and assess and address cyber-infrastructure needs. The NSF EPSCoR grant, combined with the National Institutes of Health Centers of Biomedical Research Excellence (COBRE) Supplement grant award to Dartmouth in August 2009, adds research infrastructure in a region of the country where the lack of bandwidth presents a significant barrier to tapping regional and national resources. The COBRE Supplement will extend the core research network to include Keene State College.

“Many of our leading academic centers that are constrained by the current fiber capacity will benefit, including the Institute for the Study of Earth, Oceans and Space at UNH, the Northern New England Computing Grid that is led by Dartmouth, and the Plymouth State University Meteorology Program,” said Tom Franke, the USNH chief information officer. “The fiber optic path will also continue to the University of Vermont, creating another significant opportunity for research collaboration.”

The NECC states have created NEBC (North East Bioinformatics Collaborative), a virtual organization that facilitates research projects that require data analysis for large data sets. Pilot projects on issues such as algae blooms are planned and the regional network will enable participating states to collaborate, exchange students, and work together from remote locations by taking advantage of video conferencing and other high speed services not currently available. The majority of the funds will be used for 12 fiber strands from Manchester to Plymouth to Hanover, the electronic equipment to operate the fiber network, and support for student participants in the algae bloom studies taking place in the NECC states.

The NSF established EPSCoR to assist states that traditionally have received lower levels of federal funding. Since New Hampshire became an EPSCoR jurisdiction in 2004, more than $15 million in EPSCoR research grants have been awarded by NSF, NASA, and the departments of energy and defense. NH EPSCoR is administered by the University of New Hampshire with oversight by a 14-member committee composed of representatives from industry, government and academia.

Tags: Community College System of New Hampshire, Dartmouth College, EPSCoR, National Institutes of Health Centers of Biomedical Research Excellence, National Science Foundation, Northeast Cyperinfrastructure Consortium, Plymouth State University, Scott Valcourt, Tom Franke, University of New Hampshire, University of Vermont

Posted in NH Business Matters | Comments Off on NSF $1.2M Grant to Support Hanover-Plymouth-Manchester High Bandwidth Research and Education Network

|

CONCORD – Gov. John Lynch and the Executive Council on Wednesday approved a $4 million Business Finance Authority loan to complete a major economic development agreement between the State, Safran USA, and the City of Rochester.

CONCORD – Gov. John Lynch and the Executive Council on Wednesday approved a $4 million Business Finance Authority loan to complete a major economic development agreement between the State, Safran USA, and the City of Rochester. The funds will enable the state’s seven community colleges, located in every region of New Hampshire, to develop programs that prepare individuals for skilled employment to meet current and emerging workforce needs in advanced manufacturing in New Hampshire. The programs will focus on displaced workers and other job-seekers by providing training opportunities at multiple professional levels in skills linked to regional employment.

The funds will enable the state’s seven community colleges, located in every region of New Hampshire, to develop programs that prepare individuals for skilled employment to meet current and emerging workforce needs in advanced manufacturing in New Hampshire. The programs will focus on displaced workers and other job-seekers by providing training opportunities at multiple professional levels in skills linked to regional employment.  “The middle-mile fiber network is seen as a major opportunity for economic development. In particular, the network designed for New Hampshire has openness as its core purpose – it will enable affordable choices for all providers to reach areas of the state that have been difficult to service,” said George Bald, commissioner of the state Department of Resources & Economic Development (DRED), one of the collaborating partners involved in the grant application. “The Network New Hampshire Now proposal puts the state on par with international fiber optic broadband capacity and capability.”

“The middle-mile fiber network is seen as a major opportunity for economic development. In particular, the network designed for New Hampshire has openness as its core purpose – it will enable affordable choices for all providers to reach areas of the state that have been difficult to service,” said George Bald, commissioner of the state Department of Resources & Economic Development (DRED), one of the collaborating partners involved in the grant application. “The Network New Hampshire Now proposal puts the state on par with international fiber optic broadband capacity and capability.” Funds are being awarded through the NSF’s EPSCoR (Experimental Program to Stimulate Competitive Research) Office’s Research Infrastructure Improvement Program Track-2 grant (RII Track-2). The University of New Hampshire, which hosts the New Hampshire EPSCoR Office, is the grant recipient. The University System of New Hampshire operates the current network that serves its four institutions and provides Internet and connectivity services to the Community College System of New Hampshire, and several K-12 schools, libraries, public service centers, and public health and safety organizations across the state. These funds will, in part, help advance larger efforts to develop a regional optical network that will have significantly greater bandwidth speed and help address current and future bandwidth demands.

Funds are being awarded through the NSF’s EPSCoR (Experimental Program to Stimulate Competitive Research) Office’s Research Infrastructure Improvement Program Track-2 grant (RII Track-2). The University of New Hampshire, which hosts the New Hampshire EPSCoR Office, is the grant recipient. The University System of New Hampshire operates the current network that serves its four institutions and provides Internet and connectivity services to the Community College System of New Hampshire, and several K-12 schools, libraries, public service centers, and public health and safety organizations across the state. These funds will, in part, help advance larger efforts to develop a regional optical network that will have significantly greater bandwidth speed and help address current and future bandwidth demands.