Great Bay Community College’s CNC training program is collaboration with SIG Sauer and our friends at AMPed NH explain its great value to students and employers. Ed.

Innovative boot-camp-style training programs offered by New Hampshire’s Advanced Manufacturing Partnerships in Education are benefiting not only scores of community college students, but also employers statewide.

Programs like Great Bay Community College’s CNC Production boot camp can save precision manufacturers money and time.

Programs like Great Bay Community College’s CNC Production boot camp can save precision manufacturers money and time by teaching the exact hard and soft skills they require, using the same equipment they use. Learning takes place away from production floors, allowing staff to focus on meeting product deadlines and exceeding standards. At the same time, boot camps can turn over new qualified candidates in a matter of weeks, building a healthy pipeline of qualified career prospects.

Offered in an accelerated eight-week format, the CNC Production boot camp is instructed by field experts and offered on-site at AMPed NH industry partner SIG Sauer’s state-of-the-art firearms manufacturing facility on Pease International Tradeport.

Collaboration starts at the very beginning. Community colleges work in concert with industry partners to develop and deliver specifically targeted training programs such as the CNC (computer numerically controlled) boot camp, which readies students for high-demand, well-paying CNC machining careers.

But job seekers aren’t the only ones clambering to sign up. Current SIG Sauer employees, with support from their company, are also receiving training in preparation for advancement.

Freedom Chandavong, 23, of Newmarket, a two-year employee at SIG, started in packaging and shipping and is already advancing within the company. He’s in the boot camp to prepare for a career in composite component production. SIG Sauer supports his ambitions by providing tuition reimbursement and time to train.

Just two days into boot camp, Chandavong said, the depth of topics covered was impressive.

“We were already getting into hands-on simulation training,” Chandavong said. Simulators allow students to identify and correct design and production problems in a safe, supportive learning environment before moving on to actual production equipment.

“In today’s precision manufacturing, ‘good enough’ doesn’t count,” said Chandavong, and boot camp has bolstered his confidence and determination. “SIG has made a commitment to me, and I’m going to return that commitment. I’m not going to fail them. For me, this is not a job; this is a career – and with the composites industry growing, there’s a future here.”

The commitment is not unusual, as exhibited by the students who routinely hang back in the lab, celebrating new breakthroughs even as break times begin.

“The application process does a good job to identify those with passion,” said boot camp program developer Sean Hoeing.

Innovative boot-camp-style training programs benefit students and employers.

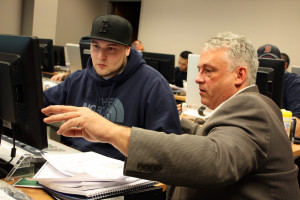

The thought was echoed by instructor Jeff Bean, an inventor and engineer whose own products are sold nationally and used in the teaching lab.

“It’s impressive,” Bean said. “They come in at different levels. They tend to be hands-on learners, and that’s what we want. That, combined with patience and attention to detail.

“We get to see them at the beginning of their training and then as they progress,” Bean said. “There are so many career paths they can choose.”

Indeed, the boot camp model has been a successful workforce solution for AMPed NH industry partners all over the state, who in years past have reported concerns that the pool of these high-tech employees was drying up.

Many students from AMPed NH’s myriad industry-approved advanced manufacturing certificate and degree programs, have already been hired by partners like SIG Sauer, who view the programs as reliable recruiting grounds for their growing operations.

The boot camp’s location itself speaks to that growth, as well as the demand for a more robust STEM (science, technology, engineering and math) workforce; SIG Sauer expanded to the site after outgrowing operations in Exeter. In addition to its Exeter and Pease sites, the company operates a training center in Epping and is opening another facility in Dover, as well as sites outside America. Combined, dozens of new hires are anticipated in the coming months locally.

Computer-numerical controlled machines are widely used where very precise manufacturing is required. Unlike manually operated equipment of the past, CNC machines shape components automatically by reading computer design code. They are faster and more versatile than ever before.

Under AMPed NH, funded by a $20 million federal TAACCCT grant from DOL’s Employment and Training Administration, NH’s seven community colleges offer dozens of programs in disciplines including robotics & automation; electronics and electromechanics; advanced machine tool, composites and welding technologies; and engineering & programming.

To learn about upcoming CNC Production boot camps, contact Sean Hoeing at shoeing@ccsnh.edu. To learn about all advanced manufacturing programs offered by AMPed NH, visit www.ampednh.com.

Desiree Crossley

Marketing Coordinator

Advanced Manufacturing Partnerships in Education

Community College System of NH