The New Hampshire Manufacturing Extension Partnership (NH MEP) today announced the results of the first national survey of world-class manufacturers, hailing the findings as valuable to both state policymakers and New Hampshire companies.

Based on an in-depth national survey of more than 2,500 manufacturers, including 74 firms in New Hampshire, the study identifies six crucial strategies necessary for world-class manufacturing success. The most unique aspect of the ground-breaking study, however, is the evaluation instrument utilized in the study. It provided participating manufacturers with a detailed assessment of how their management practices compare to global industry leaders and can evaluate whether individual firms are implementing the procedures and strategies that will enable them to thrive and succeed in the coming decade.

Based on an in-depth national survey of more than 2,500 manufacturers, including 74 firms in New Hampshire, the study identifies six crucial strategies necessary for world-class manufacturing success. The most unique aspect of the ground-breaking study, however, is the evaluation instrument utilized in the study. It provided participating manufacturers with a detailed assessment of how their management practices compare to global industry leaders and can evaluate whether individual firms are implementing the procedures and strategies that will enable them to thrive and succeed in the coming decade.

“The Next Generation Manufacturing Study is probably the most exhaustive and detailed survey of the US manufacturing base ever conducted. In today’s climate of globalization and the threat of lost manufacturing jobs, it’s important to know where the U.S. stands as a player in the international market. The study was also illustrative for Graphicast, as it highlighted where we stand compared to the more than 1,000 companies that responded to the study. This information gives us a clear path to follow to achieve world class status in technology and service,” said Val Zanchuk, president of Jaffrey-based Graphicast.

New Hampshire manufacturers like Graphicast that participated in the study received a free customized benchmarking report comparing their progress to the overall state and national results. Each confidential benchmarking report was prepared by the respected research and strategic consulting firm, the MPI Group.

Commissioned by Manufacturing Extension Partnership (MEP) centers across the country, including NH MEP, and the American Small Manufacturing Coalition, the study offers the most detailed description yet of what it takes for American manufacturers to compete in the global economy. The study was designed as the first step in a long-term effort to help U.S. manufacturers survive the recession and renew America’s manufacturing leadership over the next decade.

“New Hampshire’s economic recovery depends on the ability of its manufacturers to maintain profitability in the face of fierce competition. Manufacturing remains the state’s largest industry in terms of gross state product, accounting for more than 13 percent of state GDP. The challenge to policymakers is not to give up on manufacturing but to support the transformation of the state’s manufacturing sector into a faster, more flexible industry capable of outperforming their non-world-class peers,” said Zenagui Brahim, NH MEP director of operations.

“New Hampshire’s economic recovery depends on the ability of its manufacturers to maintain profitability in the face of fierce competition. Manufacturing remains the state’s largest industry in terms of gross state product, accounting for more than 13 percent of state GDP. The challenge to policymakers is not to give up on manufacturing but to support the transformation of the state’s manufacturing sector into a faster, more flexible industry capable of outperforming their non-world-class peers,” said Zenagui Brahim, NH MEP director of operations.

“The study itself is only the first step in NH MEP’s efforts to assist local manufacturers,” Brahim stated. “Although the national study is complete, New Hampshire manufacturers can take advantage of the evaluation instrument and work with NH MEP project managers to conduct an assessment of their company’s strategic policies, investments and performance. Every manufacturer in the state has the ability to utilize this valuable new resource.”

The Keys to Next Generation Manufacturing Success

Next Generation Manufacturing (NGM) refers to a framework of strategies that will drive manufacturing growth in the 21st century. Developed by leading manufacturers, industry thought leaders and the MEP centers, Next Generation Manufacturing reflects the best practices and performance strategies of world class companies. To remain competitive, manufacturers in New Hampshire and across the country need to achieve world-class performance in at least some of these key areas. The study identifies six essential strategies:

• Customer-focused innovation: Deliver new and better customer solutions at a faster pace than the competition.

• Advanced talent management: Secure a competitive performance advantage by having superior systems in place to recruit, hire, develop and retain talent.

• Systemic continuous improvement: Record annual productivity and quality gains that exceed the competition through a companywide commitment to continuous improvement.

• Extended enterprise management: Leverage a flexible network of supply chains and partnerships to provide competitive advantages of speed, cost and quality.

• Sustainable product and process development: Design and implement waste and energy-use reductions at a level that provides superior cost performance and recognizable customer value.

• Global engagement: Secure business advantages through people, partnerships and systems capable of engaging global markets, talent and resources.

The survey administered to the initial 1,500 companies nationwide employed 63 questions to drill down and measure each firm’s progress, or lack of progress, in implementing strategies in these six essential areas.

Sobering Findings

• A serious gap exists between the strategies that New Hampshire and U.S. manufacturers believe are critical to their future success and their actual progress in implementing those strategies. Currently, only a fraction of New Hampshire manufacturers are at or near world-class in any of the six NGM strategies.

• Small and midsize manufacturers are less likely than larger firms to be at or near world-class status in each of the NGM strategies. One-third of respondents nationwide with less than $10 million in revenue were not at or near world-class in any strategy, compared to just 14% of manufacturers with more than $100 million in revenue.

• Measurement systems are inadequately deployed. Even in one of the most fundamental and easiest-to-measure areas – process improvement – 46% of respondents in New Hampshire and across the country had no measurement system or only ad hoc measurement systems.

• Effective partnerships with employees, suppliers and regional support organizations are the exception rather than the norm. Nationwide, a majority of respondents (56%) engage less than half of their employees in improvement initiatives, falling far short of industry best practices that require company-wide participation. In New Hampshire the results were modestly better, but 45% of respondents still engage less than half of their employees.

• In New Hampshire and across the nation approximately 40% of companies fail to reach or approach world-class status in the ability of their supply chains to respond to unexpected customer demand for existing products. In part this is due to the failure of companies to implement supply-chain measurement systems. More than 45% of New Hampshire firms said that they have no measurement system or only ad hoc measurement systems in place to review the return from supply chain management and collaboration.

• Energy efficiency remains a weak link. Less than five percent of New England firms are at or near world-class status in terms of annual reduction of energy consumption per unit of product output.

• Only 28% of respondents nationwide and 35% of firms in New Hampshire believe global engagement is highly important, despite a near-term future in which markets, talent, competitors and partner opportunities are growing faster outside the U.S. than within its borders.

New England’s Strength: Advanced Manufacturing

The survey data reveal a sobering picture of the challenges facing American manufacturers. But the report highlights an important distinction that characterizes New England manufacturers in general and New Hampshire manufacturing sector in particular. New England possesses a robust advanced manufacturing cluster that distinguishes itself from manufacturers nationwide in some very notable ways.

• New England manufacturers devote more resources to new product development and R&D than their counterparts nationwide.

o 23.8% of New England manufacturers invest more than ten percent of sales in new product development versus 14.6% of firms nationwide.

o 48.9% of New England manufacturers dedicate more than five percent of their workforce to new product development versus 34.6% of firms nationwide.

• New England manufacturers launch significantly more new products annually than their counterparts nationally (23.5% of New England manufacturers launch more than ten percent of their total SKUs annually versus 15.7% nationally.)

• New England manufacturers derive a significantly larger percentage of annual sales from new products than their counterparts nationally (33.7% of New England manufacturers derive at least one-quarter of their annual sales from products introduced in the last three years versus 24.8% of manufacturers nationally.)

• New England manufacturers derive significantly more value-added per employee than their counterparts nationwide, with 34.9% of New England respondents reporting that they receive more than $125,000 per employee versus 28.0% nationwide achieving that level of value-added.

These findings confirm the results of another recent study on manufacturing conducted by Deloitte Consulting LLP for the New England Council, which found that New England enjoys a strong cluster of advanced manufacturers whose productivity improvements have been transformational. That report, Reexamining Advanced Manufacturing in a Networked World: Prospects for a Resurgence in New England, noted that advanced manufacturing has reversed the decline associated with traditional manufacturing in New England by developing a talent-rich network of advanced manufacturers with skilled workforces capable of creating complex product solutions.

These findings confirm the results of another recent study on manufacturing conducted by Deloitte Consulting LLP for the New England Council, which found that New England enjoys a strong cluster of advanced manufacturers whose productivity improvements have been transformational. That report, Reexamining Advanced Manufacturing in a Networked World: Prospects for a Resurgence in New England, noted that advanced manufacturing has reversed the decline associated with traditional manufacturing in New England by developing a talent-rich network of advanced manufacturers with skilled workforces capable of creating complex product solutions.

“New England manufacturers clearly out-perform their counterparts nationally in terms of developing new products and gaining a higher value-add from each employee. But the Next Generation Manufacturing study clearly shows how far many manufacturers still have to go to reach world-class status,” said NH MEP Operations Director Brahim. “In many strategic areas our state’s firms are just as challenged as manufacturers nationwide and need to take major steps to improve their performance or else risk being left behind by the global competition. New England’s economic future will be determined by how the region’s manufacturers respond to this challenge.”

Attention manufacturers! Growth and sustainability will be the theme of the seventh annual Governor’s Advanced Manufacturing and High Technology Summit, scheduled to take place from 7 a.m. to 2 p.m. on Tuesday, Oct. 13, at the Grappone Conference Center in Concord.

Coordinated by the New Hampshire Division of Economic Development, the New Hampshire Manufacturing Extension Partnership and the Business & Industry Association of New Hampshire, the summit will provide participants with tips for accelerating reliable growth in their businesses.

Sponsors of the event are Citizens Bank, the Society of Manufacturing Engineers, the Association for Operations Management and New Hampshire Business Review.

Registration fee for the summit is $85 per participant; lunch is included. Interested parties can sign up online by visiting http://www.acteva.com/ttghits.cfm?EVA_ID=23444.

Based on an in-depth national survey of more than 2,500 manufacturers, including 74 firms in New Hampshire, the study identifies six crucial strategies necessary for world-class manufacturing success. The most unique aspect of the ground-breaking study, however, is the evaluation instrument utilized in the study. It provided participating manufacturers with a detailed assessment of how their management practices compare to global industry leaders and can evaluate whether individual firms are implementing the procedures and strategies that will enable them to thrive and succeed in the coming decade.

Based on an in-depth national survey of more than 2,500 manufacturers, including 74 firms in New Hampshire, the study identifies six crucial strategies necessary for world-class manufacturing success. The most unique aspect of the ground-breaking study, however, is the evaluation instrument utilized in the study. It provided participating manufacturers with a detailed assessment of how their management practices compare to global industry leaders and can evaluate whether individual firms are implementing the procedures and strategies that will enable them to thrive and succeed in the coming decade. “New Hampshire’s economic recovery depends on the ability of its manufacturers to maintain profitability in the face of fierce competition. Manufacturing remains the state’s largest industry in terms of gross state product, accounting for more than 13 percent of state GDP. The challenge to policymakers is not to give up on manufacturing but to support the transformation of the state’s manufacturing sector into a faster, more flexible industry capable of outperforming their non-world-class peers,” said Zenagui Brahim, NH MEP director of operations.

“New Hampshire’s economic recovery depends on the ability of its manufacturers to maintain profitability in the face of fierce competition. Manufacturing remains the state’s largest industry in terms of gross state product, accounting for more than 13 percent of state GDP. The challenge to policymakers is not to give up on manufacturing but to support the transformation of the state’s manufacturing sector into a faster, more flexible industry capable of outperforming their non-world-class peers,” said Zenagui Brahim, NH MEP director of operations. These findings confirm the results of another recent study on manufacturing conducted by Deloitte Consulting LLP for the New England Council, which found that New England enjoys a strong cluster of advanced manufacturers whose productivity improvements have been transformational. That report, Reexamining Advanced Manufacturing in a Networked World: Prospects for a Resurgence in New England, noted that advanced manufacturing has reversed the decline associated with traditional manufacturing in New England by developing a talent-rich network of advanced manufacturers with skilled workforces capable of creating complex product solutions.

These findings confirm the results of another recent study on manufacturing conducted by Deloitte Consulting LLP for the New England Council, which found that New England enjoys a strong cluster of advanced manufacturers whose productivity improvements have been transformational. That report, Reexamining Advanced Manufacturing in a Networked World: Prospects for a Resurgence in New England, noted that advanced manufacturing has reversed the decline associated with traditional manufacturing in New England by developing a talent-rich network of advanced manufacturers with skilled workforces capable of creating complex product solutions. We’ve just uploaded three new videos – one detailing all of the happenings at Greenerpalooza II, another chronicling our “No Bull Football Jam” at the Verizon Wireless Arena and the last showcasing the “No Bull Motorcycle Run” that we developed in coordination with our friends at Laconia Harley Davidson.

We’ve just uploaded three new videos – one detailing all of the happenings at Greenerpalooza II, another chronicling our “No Bull Football Jam” at the Verizon Wireless Arena and the last showcasing the “No Bull Motorcycle Run” that we developed in coordination with our friends at Laconia Harley Davidson. With that goal as a backdrop, we are happy to unveil the newest addition to No Bull TV, a short video that combines dodgeball with business doublespeak. For those of you who’ve forgotten, No Bull TV is the New Hampshire Division of Economic Development’s new YouTube channel that is geared toward providing a video component to our communications efforts – right now, the channel is being used to draw attention to this blog and our social media efforts. As we speak, we are sifting through footage culled from the No Bull Motorcycle Run, Greenerpalooza and Social Media Night at the Manchester Wolves and plan to upload those videos soon. We will also be featuring some of our upcoming events, our Open Invitation initiative and our Innovation Rocks winners.

With that goal as a backdrop, we are happy to unveil the newest addition to No Bull TV, a short video that combines dodgeball with business doublespeak. For those of you who’ve forgotten, No Bull TV is the New Hampshire Division of Economic Development’s new YouTube channel that is geared toward providing a video component to our communications efforts – right now, the channel is being used to draw attention to this blog and our social media efforts. As we speak, we are sifting through footage culled from the No Bull Motorcycle Run, Greenerpalooza and Social Media Night at the Manchester Wolves and plan to upload those videos soon. We will also be featuring some of our upcoming events, our Open Invitation initiative and our Innovation Rocks winners. In terms of the dodgeball shoot (

In terms of the dodgeball shoot ( Exeter-based Sig Sauer’s P250 was designed specifically to address the future needs of the military, law enforcement and civilian shooters and features six different ergonomic combinations to accommodate varying hand sizes. Hailed by Gun World as “a pistol for all seasons,” the P250 is also renowned for having 30-40 percent fewer parts than a traditional semi-automatic pistol.

Exeter-based Sig Sauer’s P250 was designed specifically to address the future needs of the military, law enforcement and civilian shooters and features six different ergonomic combinations to accommodate varying hand sizes. Hailed by Gun World as “a pistol for all seasons,” the P250 is also renowned for having 30-40 percent fewer parts than a traditional semi-automatic pistol.

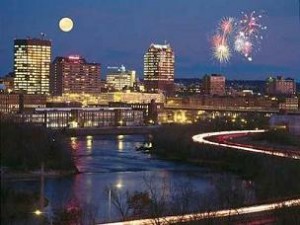

Here’s what the story said about the Queen City:

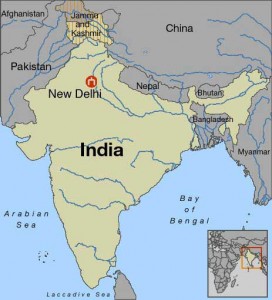

Here’s what the story said about the Queen City: Both large and small U.S. firms find India a lucrative market, especially for in the following sectors – aerospace and defense, airport and ground handling, computer technology, education services, electric power and transmission equipment, food processing, medical equipment, telecom equipment, retail and franchising, textile machinery, pollution control equipment and mining equipment. India’s GDP, growing at 6.7% (for 2008-09), makes it one of the fastest growing economies in the world and the second fastest in Asia. India has potential for a sustained growth of 8-10% for the next couple of years.

Both large and small U.S. firms find India a lucrative market, especially for in the following sectors – aerospace and defense, airport and ground handling, computer technology, education services, electric power and transmission equipment, food processing, medical equipment, telecom equipment, retail and franchising, textile machinery, pollution control equipment and mining equipment. India’s GDP, growing at 6.7% (for 2008-09), makes it one of the fastest growing economies in the world and the second fastest in Asia. India has potential for a sustained growth of 8-10% for the next couple of years. In addition, a 2007 survey of small business owners by the Red Cross and FedEx showed that while 94 percent of small business owners believed there was a potential for disaster to seriously disrupt their business, less than half felt prepared for even a one-week disruption.

In addition, a 2007 survey of small business owners by the Red Cross and FedEx showed that while 94 percent of small business owners believed there was a potential for disaster to seriously disrupt their business, less than half felt prepared for even a one-week disruption.